Project Overview

The project at Smurfit Kappa Norwich was a major undertaking, involving the complete replacement of the factory’s 11,500m² roof. The primary challenges were rooted in the facility’s operational nature. This meant the roof refurbishment had to be meticulously planned and executed without impacting the factory’s ongoing processes. Weatherproofing Advisors worked in close collaboration with Knight Frank to conduct a thorough condition report of the roof, which included composite cladding, asbestos-lined built-up systems, and felt roofs.

With such diverse roofing systems and extensive wear from years of exposure, the phased approach was adopted. Over the course of ten months, five distinct phases of roof replacement were implemented, ensuring minimal disruption. Each phase was carefully coordinated to maintain factory operations, keeping the workforce and machinery safe.

Weatherproofing Advisors were successfully appointed to complete major roofing works over a live factory

Smurfit Kappa Norwich, strategically located on Fishergate Street in the bustling heart of the city center, represents a significant operational hub running around the clock, every day of the week. The factory’s extensive layout, housing expensive machinery across various sections, posed considerable challenges for our project. Our primary task involved meticulously stripping the existing roof and replacing it with a new, profiled metal buildup system, all while ensuring that the factory’s operations remained uninterrupted.

This complex process demanded exceptional levels of planning and communication, a feat adeptly managed by Weatherproofing Advisors. Collaborating with Knight Frank, our team undertook a comprehensive condition report of the expansive 11,500m² roof, which comprised composite cladding, built-up systems with asbestos liners, and felt roofs. The roofs aged infrastructure had led to severe water ingress, significantly affecting daily operations and manifesting typical deterioration signs.

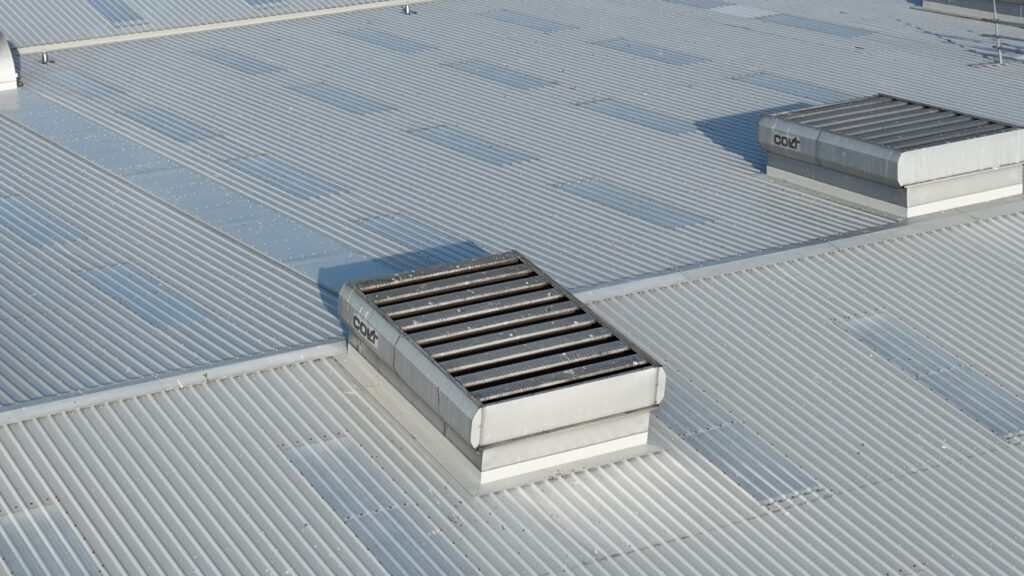

The multifaceted nature of the roofing systems necessitated a phased approach, dividing the project into five distinct phases spread over ten months. This phased strategy ensured minimal disruption to Smurfit Kappa’s ongoing operations. The new roofing system, now compliant with current building regulations, was implemented with support from our trusted suppliers, including Joriside, Hambleside Danelaw, Ampteam, and IKO.

A new siphonic system was installed in the central valley alongside a comprehensive safety line system, facilitating a robust aftercare package designed to uphold the 25-year guarantee. The successful completion of this project not only revitalised the facility’s roof but significantly enhanced the operational reliability and safety standards of Smurfit Kappa Norwich, securing its place as a critical player in the city’s industrial landscape.

The deteriorating roof was stripped and replaced with a new profiled metal buildup system, compliant with modern building regulations. This comprehensive solution involved trusted suppliers like Joriside, Hambleside Danelaw, Ampteam, and IKO. In addition to the roofing system upgrade, a new siphonic drainage system was installed in the central valley to improve water management, further preventing the water ingress issues that had plagued the facility.

Safety was a key concern, and Weatherproofing Advisors also implemented a new safety line system that allows for safe and secure access for ongoing roof maintenance. The entire roofing solution was completed with an aftercare package and a 25-year guarantee, ensuring Smurfit Kappa Norwich benefits from long-term security and operational stability.