Project Overview

Yeovil District Hospital NHS Trust, in collaboration with LED Architects, embarked on a pivotal roof refurbishment journey at their primary healthcare facility. Entrusting the expertise of Weatherproofing Advisors (WPA), the project aimed to replace the existing built-up felt, warm roof construction that had surpassed its functional lifespan. The primary objectives were to establish a watertight roof system, ensuring zero water ingress, and to lay the foundation for future modular unit installations. The refurbishment featured a torch-applied bituminous felt system, innovative sumped gutter details, “Bigfoot” style roof mounts for air handling units, and a specialized solution for an existing modular building. A highlight of the project was the introduction of a vibrant red walkway, ensuring clear and safe access to roof-mounted equipment. This comprehensive approach resulted in a state-of-the-art roofing solution that seamlessly blends safety, durability, and aesthetics, setting a benchmark for future infrastructural endeavors.

Weatherproofing Advisors were appointed to undertake the Level 3 Roof refurbishment project at Yeovil District Hospital

Working with Yeovil District Hospital NHS Trust and their appointed partner, LED Architects, WPA was commissioned to survey the roof and provide a detailed report of its condition and to consider the appropriate solutions. Following the survey, it was determined that the existing roof is a built-up felt, warm roof construction covering a screed laid to falls. The felt was suffering from large blisters from water ingress throughout the roof, causing laps to fail and more water to penetrate the system. The roof was considered to have reached the end of its serviceable life and WPA provided a solution that removed the defects from the old roof and provided a new built-up felt system that met the client’s key objectives.

The key objectives for the client were to ensure a watertight roof covering with no water ingress and to provide a surface suitable for the future installation of modular units.

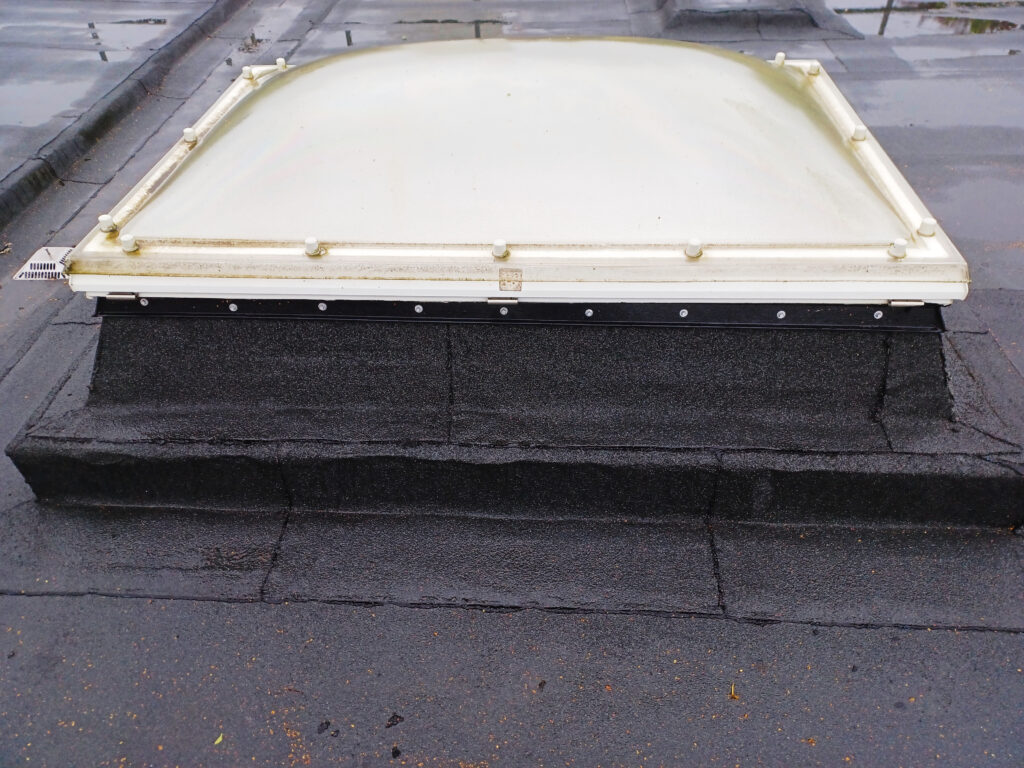

WPA removed the blistered and defective areas of the roof and installed a torch-applied bituminous felt system with two sumped gutter details running the length of the roof. Existing air handling units were temporarily raised to receive the new felt covering and replaced on to new “Bigfoot” style roof mounts. There were multiple roof lights & and penetrations on the roof which were carefully detailed to ensure the integrity of the system. There is an existing modular building that has been built on top of the Level 3 roof area that requires a different solution owing to the material that the modular building is constructed from. Using a torch-applied solution here was not deemed appropriate, a liquid coating solution was installed here after consultation with the supplier to ensure that the 20-year warranty is maintained. To ensure a clear, demarcated access route to all roof mounted plant, a red walkway has been incorporated on to the field area and has replaced the use of paving slabs and thus reducing the weight loading on the structure.

Before

After

The Initial Assessment

Upon our commission, our first task was to conduct a thorough survey of the roof. The objective was to provide a detailed report on its condition and to evaluate the most suitable solutions. The assessment revealed that the existing roof was a built-up felt, warm roof construction covering a screed laid to falls. Unfortunately, the felt was plagued with significant blisters from water ingress, causing laps to fail and allowing more water to seep into the system. It was evident that the roof had reached the end of its serviceable life.

Our Solution

Understanding the client’s key objectives was paramount. They needed a watertight roof covering with zero water ingress and a surface apt for the future installation of modular units.

We took the initiative to remove the blistered and defective areas of the roof. Our team then installed a torch-applied bituminous felt system, incorporating two sumped gutter details that ran the length of the roof. Existing air handling units were temporarily elevated to accommodate the new felt covering and were subsequently placed onto new “Bigfoot” style roof mounts.

The roof had multiple lights and penetrations, which we meticulously detailed to ensure the system’s integrity. An existing modular building on the Level 3 roof area presented a unique challenge due to its construction material. A torch-applied solution wasn’t suitable here. Instead, after consulting with the supplier, we opted for a liquid coating solution, ensuring the 20-year warranty remained intact.

To guarantee a safe and clear access route to all roof-mounted plant, we integrated a red walkway onto the field area. This replaced the previously used paving slabs, effectively reducing the weight load on the structure.

Key Highlights

- Before our intervention, paving slabs were used to demarcate a walkway on the roof.

- The sumped gutter detail around the building’s edge was carefully designed and detailed by our team, ensuring longevity and functionality.

Conclusion

At Weatherproofing Advisors, we pride ourselves on delivering top-notch solutions tailored to our client’s needs. The Level 3 Roof refurbishment at Yeovil District Hospital stands as a testament to our commitment, expertise, and dedication to excellence.