Dunelm’s Merthyr Tydfil distribution centre recently underwent a major roof and gutter refurbishment, carried out by Weatherproofing Advisors. The existing roof had become heaily weathered over time, with corrosion, failed fixings, and worn rooflights creating ongoing maintenance and safety issues. Previous patch repairs were no longer effective, and the building needed a long-term solution to protect the facility.

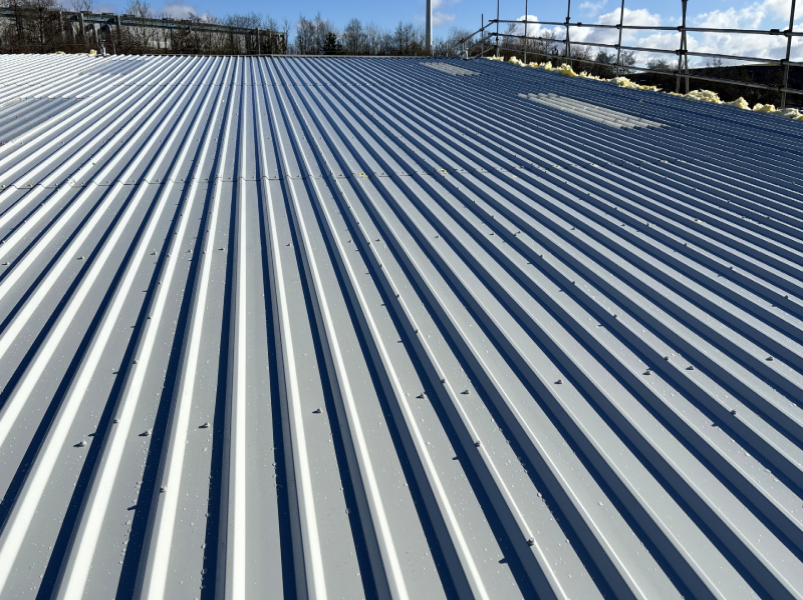

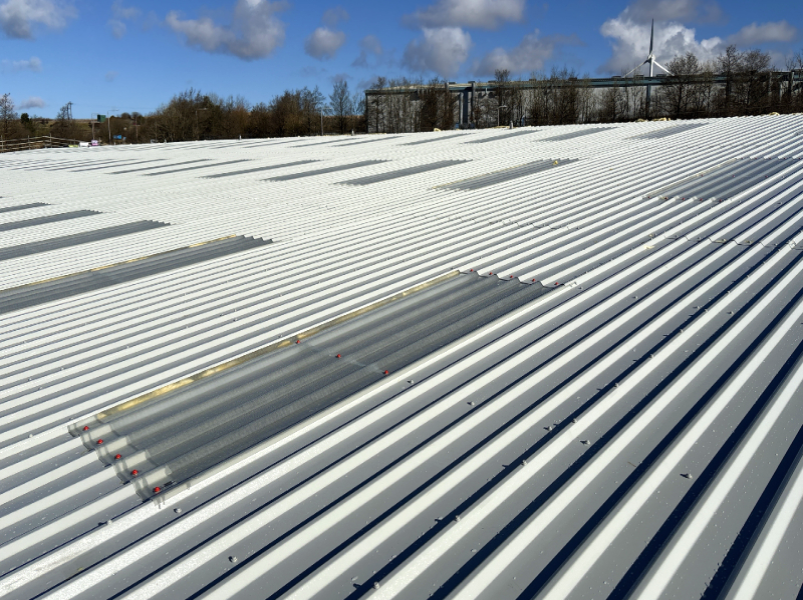

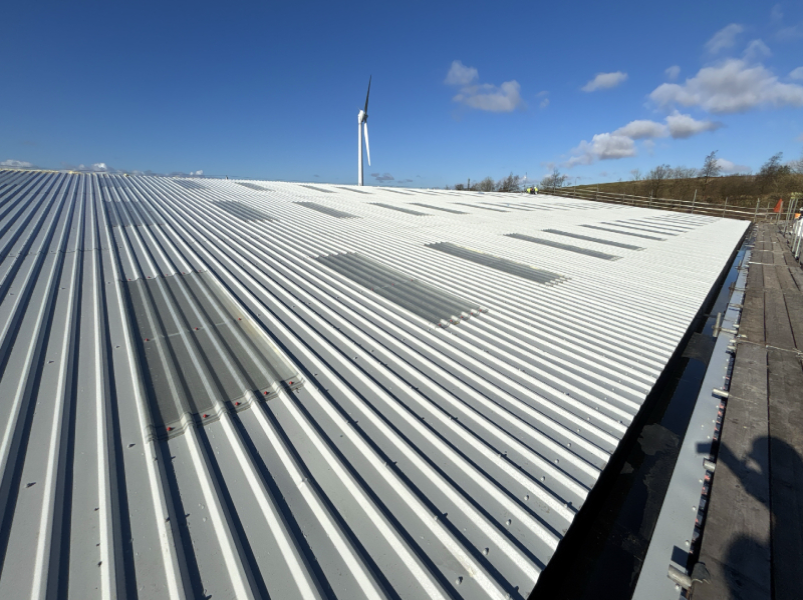

To address this, the team oversheeted the entire roof with new plastisol-coated profile sheets, installed over a bar and bracket system with upgraded quilt insulation to improve the building’s thermal performance. New rooflights were fitted to maximise natural daylight inside the warehouse, while redundant flues and penetrations were removed and the gutter systems completely relined with Unifold liners. A new mansafe system was also installed along the ridge to ensure future maintenance could be carried out safely.

The project was delivered using perimeter scaffolding and safety netting, allowing Dunelm to remain operational throughout the works. With careful planning and coordination, WPA provided a durable, energy-efficient roofing system that will protect the site for years to come and give the client confidence in the building’s long-term performance.

Weatherproofing Advisors were successfully appointed to refurbish the roof and gutters of Dunelm's Merthyr Tydfil location.

The building comprised of a shallow duo pitch metal clad roof with boundary gutters situated to the east & west elevations. The built-up roof system comprised of a metal liner panel, bar & bracket system with 200mm insulation capped off with a profiled metal roof sheet.

Multiple rooflights and penetrations remain present on the roof. The profiled metal sheet was heavily weathered and suffered from significant delamination of the protective coating. The sheet laps at the eaves and end laps were suffering with heavy cut edge corrosion and a significant portion of the fixings are either missing or have perished and require replacing.

The poppy red fixings around the rooflights had faded and were difficult to identify resulting in a health & safety risk to anyone traversing the roof for maintenance purposes. The flashings to the ridge & verges are also delaminating with evidence of historical liquid coating repairs present.

WPA provided a solution to oversheet the whole roof with new plastisol coated profile sheets, bar & bracket system and installed 160mm quilt insulation which achieved a total thermal rating of 0.15/m2K. Replacement rooflights to provide maximum levels of natural light into the building.

The gutters to both elevations were relined with Ampteam Unifold gutter liner including all stop ends, unions & outlets. All redundant flues and penetrations were removed under the advice of the client with all remaining penetrations weathered in accordance with current regulations.

A new mansafe system was installed along the ridgeline to provide safe access to enable maintenance and ensure the warranty is protected.